Proprietary technology for refining spodumene concentrate

Lower capital and operating costs due to streamlined flowsheet and lower reagent usage

Sustainable and safe process as residues are inert and readily neutralized

Soaring demand for lithium

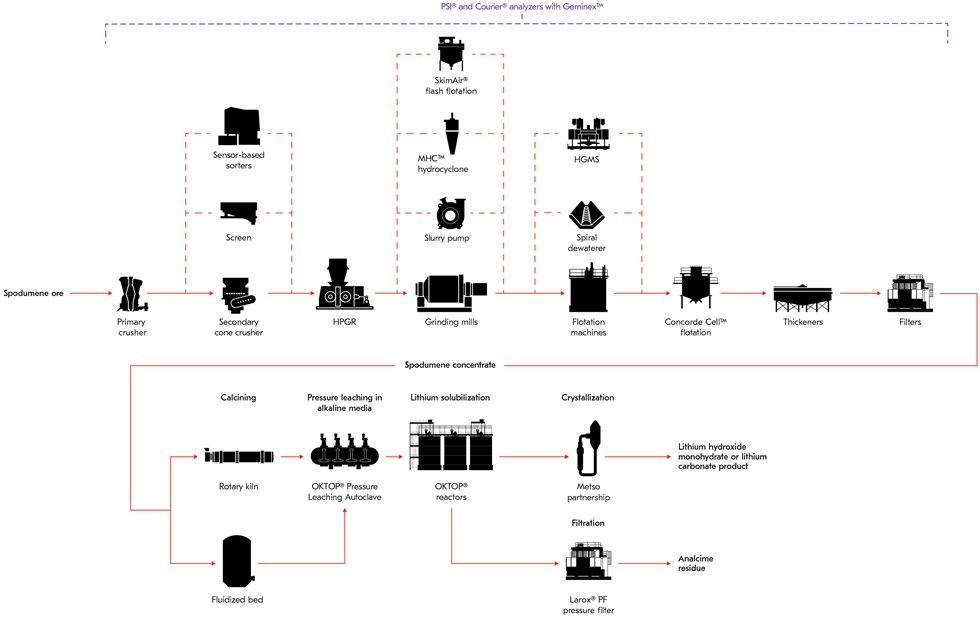

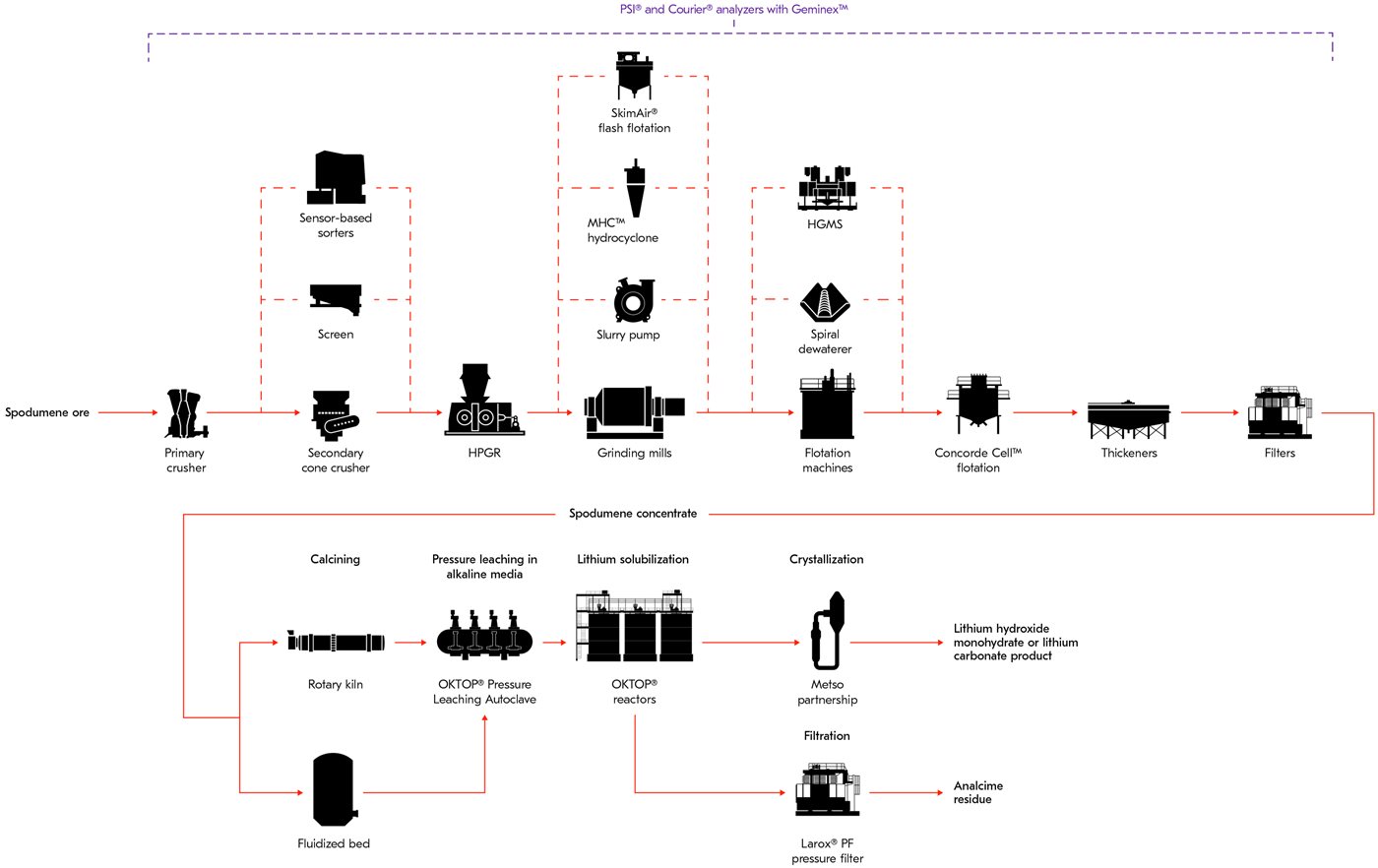

Metso is a comprehensive solution provider for major lithium operations, backed by the latest technology and decades of experience in spodumene extraction.

Our proprietary technology offers a short-cut process concept for spodumene concentrates: direct alkaline leach process for lithium extraction and solubilization, followed by crystallization of the lithium product. Furthermore, the leach process is environmentally sustainable: acid & sulphate free, without undesired crystallized salts or by-products, producing inert and neutral mineral residue for re-use or disposal.

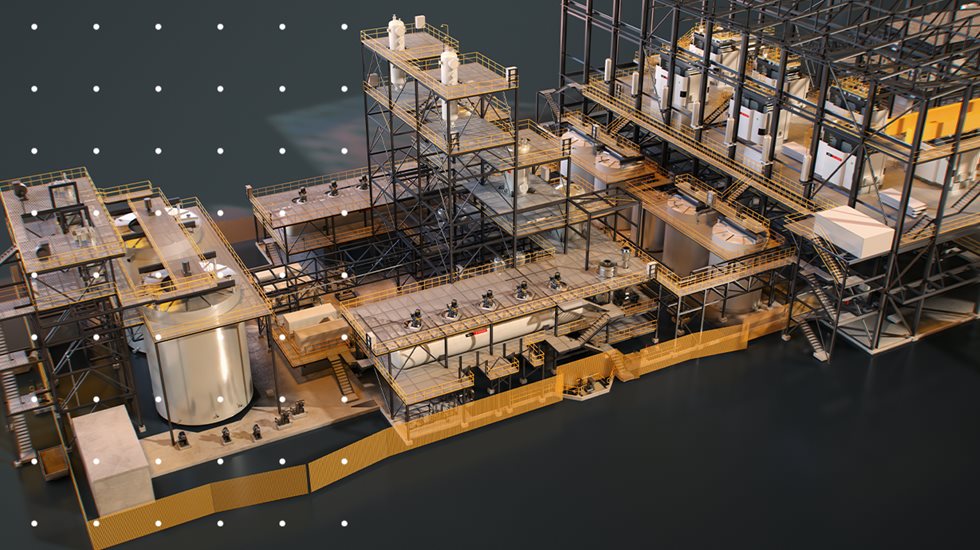

Industry’s most comprehensive scope of supply

As part of our commitment to strong and on-going research and development, we strive to develop new and improved equipment and processing technologies that satisfy the ever-changing needs of our customers. To meet the evolving needs of the battery industry, Metso has expanded its process piloting capabilities at the Pori Research Center.

We have successfully tested and piloted the process with several spodumene concentrates to produce battery-grade end product. Additionally, the alkaline leaching concept is under development to cover also other lithium minerals like petalite, zinnwaldite and lepidolite.

Sustainable lithium hydroxide technology to help our planet

Metso is providing the way for our customers to achieve the lowest GWP (Global Warming Potential) in lithium production from spodumene.

Planet positive process:

- Reduced pollution to air, water, and soil with neutral and sulfate free residues

- 40-60% reduction in water use, as well as acidification and eutrophication impact categories, based on LCIA (Life Cycle Impact Assessment) results of lithium hydroxide production

- Minimized plant footprint & embedded carbon