Benefits

Upgrades help you minimize disruption and maximize uptime

Upgrades and liner lifting tools provide additional safety for workers

Upgrades help to simplify and speed up maintenance

Long-lasting liners, and less waste using WearSense online monitoring

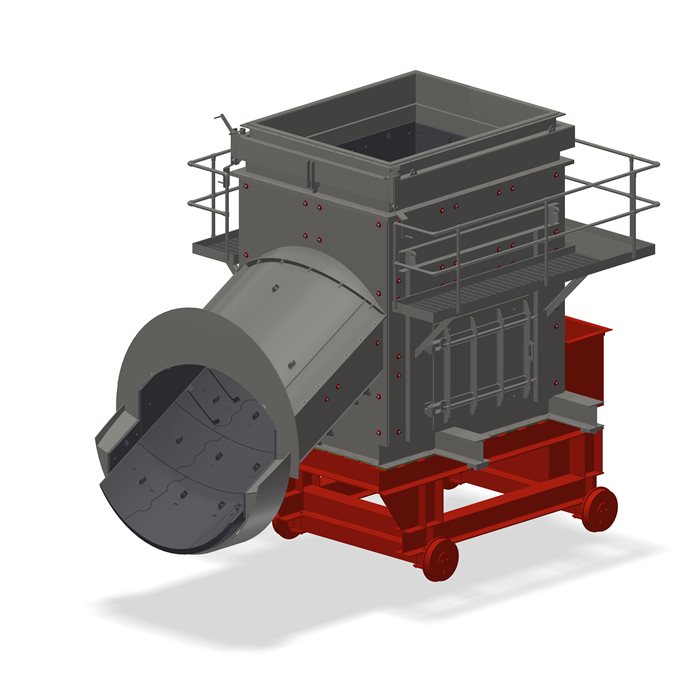

Frequent challenges

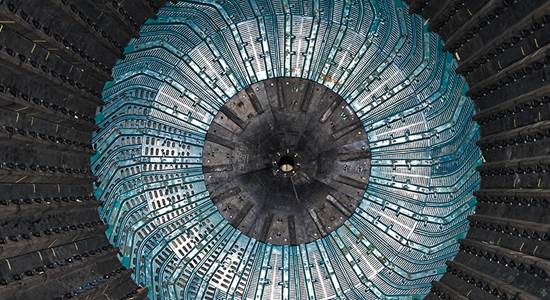

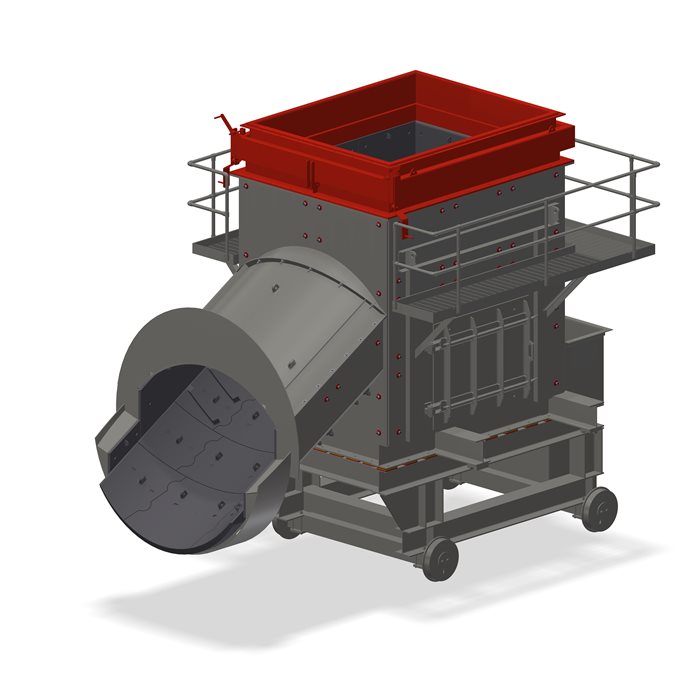

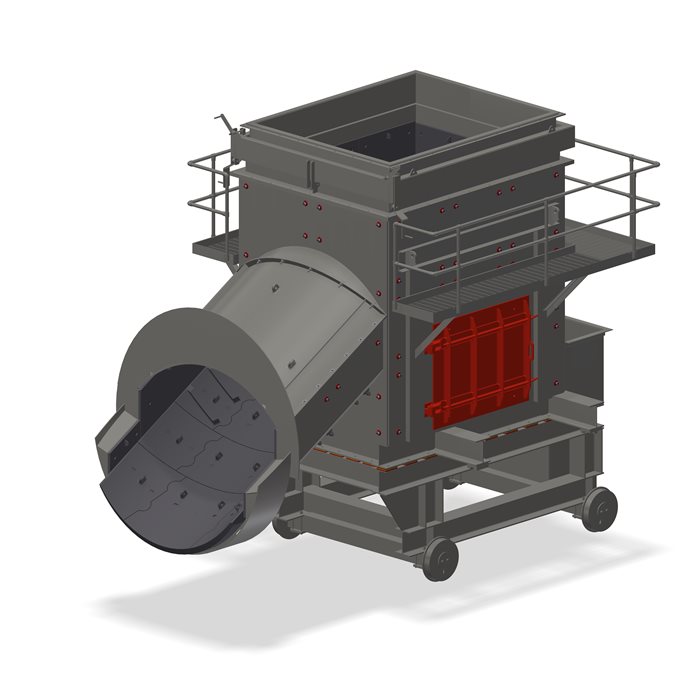

- Deep design to provide rock-bed of material, which eliminates liner wear for bottom liners

- Physical dimensions engineered to accept feed material

- Heavy steel plate and beam fabrication

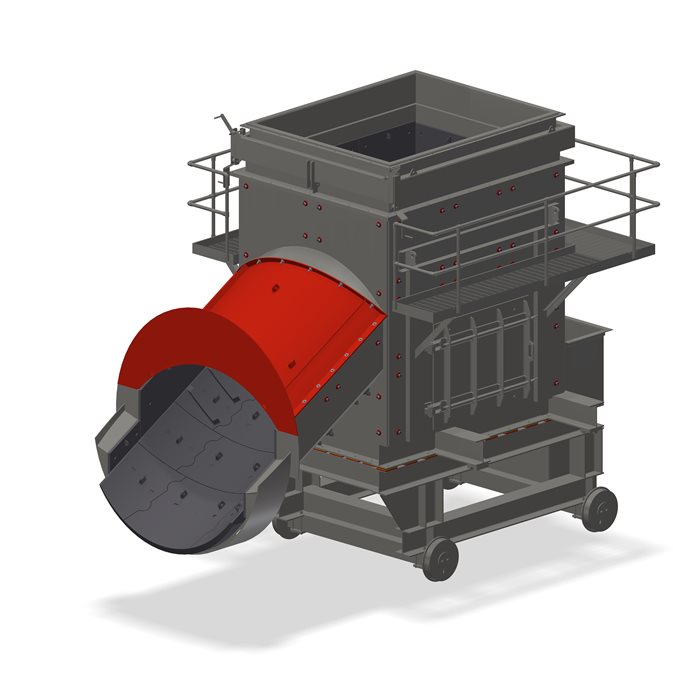

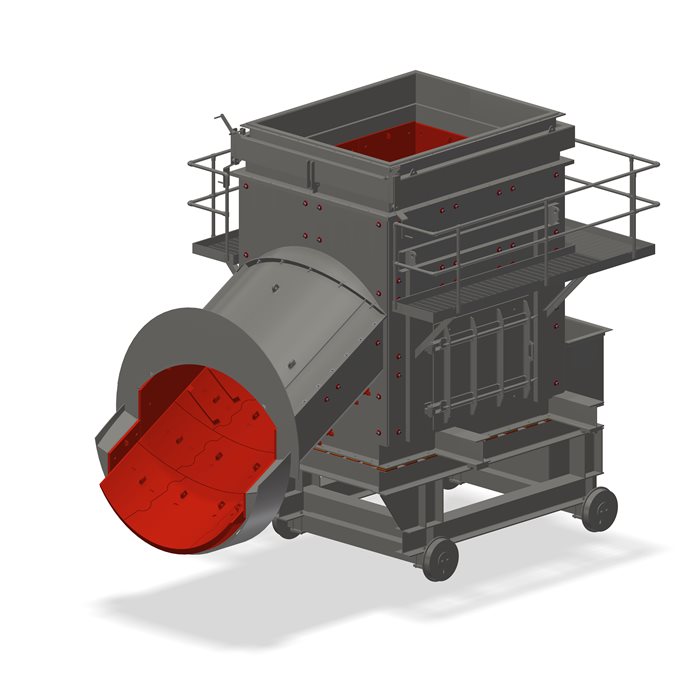

The removable chute cover offers much easier and safer access for wear liner installation and replacement.

- Reduces down-time by making liner changes faster

- Bolted cover design

- Integrated lifting lugs

- Drop channel catches and directs spillage back into the chute

Liner design upgrade

- Longer life

- Ease of replacement

- Optimized flow

Features and benefits

- Curved 3-piece design

- Easy replacement, can be replaced without removing edge liners

- Gridlock joints to prevent wash lines

- Reduced waste

- Reduced down-time

- WearSense remote wear monitoring option

Liftx liner lifting tool for added safety

- Easy to use wear liner lifting tool

- Improves safety and can eliminate weld-on or cast lifting lugs

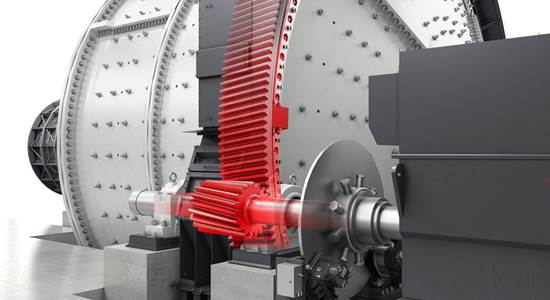

Labyrinth or inflatable design for various mill configurations.

Inflatable Seal

Allows clearance for installation and maintenance, and quick inflation with air to seal the gap when feed chute is in place.

- Can be used instead of a bolting flange for faster connection

- Allows for slight deviation of flange surfaces

Labyrinth Seal

Adjustable alignment of feed chute upper section provides robust sealing solution while hinged front panel for easy retraction of feed chute without unbolting upper section.

- Helps eliminate spillage and protects main bearing from slurry

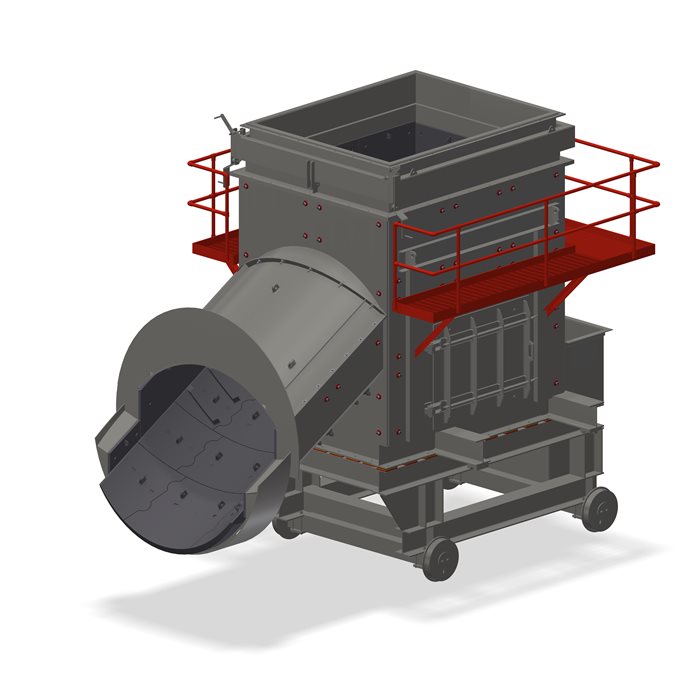

Gives operators a safe and easy way to access the upper feed chute, inspect the rock-box and perform any maintenance in the area.

- Safe and easy access to flange and seal for maintenance

- Customizable based on customers needs.

Optional add-on to offer an additional access point to the Rock-box for clean out and maintenance.

- Easy access for maintenance

- Located and placed as per customer request

Easy access for maintenance.

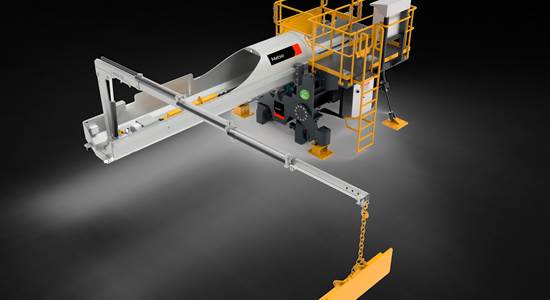

Carriage

- Sealed sleeve bearings

- Counterweight box

- Lateral beams for transport options

Trolley alignment features

- Height adjustment shim packs with built-in jacking screws

- Lateral alignment dowel pins

- Trolley to mill engagement locking pins

- Chute-trolley alignment aids

Mobile transporter to lift and position a fixed trolley

The MET is equipped with a variety of safety features to monitor loads and is backed by a comprehensive range of support services.

Hydraulic features

Feed Chute features - List of improvements

{{decodeHtmlEntities(field.label)}} |

|---|